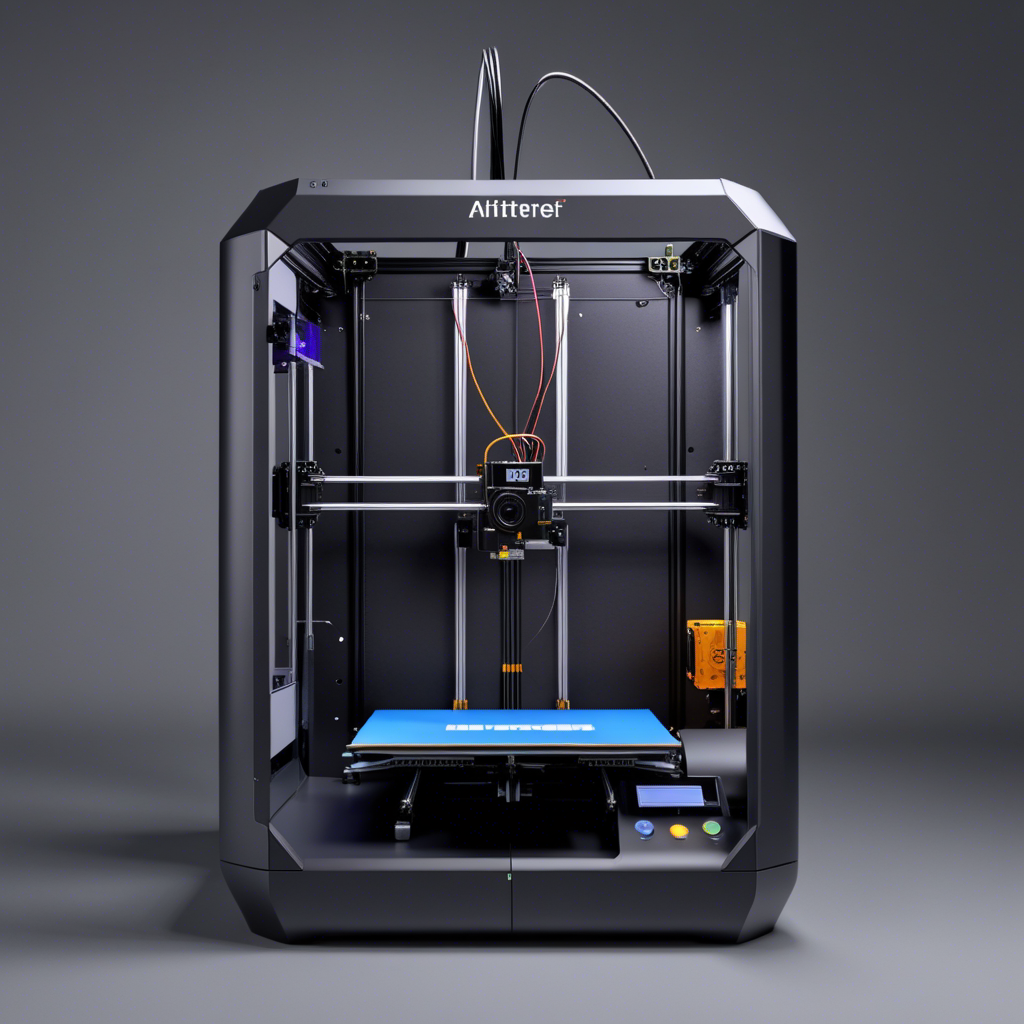

The electronics industry has been revolutionized by the advent of 3D printing technology. This technology has enabled the rapid production of complex electronic components and devices, reducing the time and cost associated with traditional manufacturing methods. In this article, we will explore the impact of 3D printing on the electronics industry and the benefits it offers.

The Rise of 3D Printing in Electronics

3D printing, also known as additive manufacturing, has been gaining popularity in the electronics industry over the past decade. This technology allows for the creation of complex shapes and structures that cannot be produced using traditional manufacturing methods. The use of 3D printing in electronics has been driven by the need for rapid prototyping, reduced production costs, and increased product complexity.

Benefits of 3D Printing in Electronics

The benefits of 3D printing in electronics are numerous. Some of the most significant advantages include:

- Rapid Prototyping: 3D printing allows for the rapid production of prototypes, reducing the time and cost associated with traditional prototyping methods.

- Increased Complexity: 3D printing enables the creation of complex shapes and structures that cannot be produced using traditional manufacturing methods.

- Reduced Production Costs: 3D printing reduces the need for tooling and molds, reducing production costs and lead times.

- Improved Product Performance: 3D printing allows for the creation of products with improved performance characteristics, such as increased strength and durability.

Applications of 3D Printing in Electronics

3D printing is being used in a wide range of applications in the electronics industry, including:

- Printed Circuit Boards (PCBs): 3D printing is being used to produce PCBs with complex geometries and structures.

- Electronic Components: 3D printing is being used to produce electronic components, such as resistors, capacitors, and inductors.

- Antennas: 3D printing is being used to produce antennas with complex geometries and structures.

- Sensors: 3D printing is being used to produce sensors with improved performance characteristics.

Challenges and Limitations

While 3D printing offers many benefits in the electronics industry, there are also several challenges and limitations to be addressed. Some of the most significant challenges include:

- Material Properties: The properties of materials used in 3D printing can be difficult to control, which can affect the performance of electronic devices.

- Scalability: 3D printing can be difficult to scale up to large production volumes, which can limit its use in high-volume manufacturing.

- Cost: The cost of 3D printing equipment and materials can be high, which can limit its adoption in some industries.

Future of 3D Printing in Electronics

The future of 3D printing in electronics is bright, with many companies and research institutions investing heavily in this technology. Some of the most significant trends and developments in 3D printing in electronics include:

- Increased Adoption: 3D printing is expected to become more widely adopted in the electronics industry, driven by the need for rapid prototyping and reduced production costs.

- Advances in Materials: Advances in materials science are expected to lead to the development of new materials with improved properties, which will enable the production of more complex and sophisticated electronic devices.

- Integration with Other Technologies: 3D printing is expected to be integrated with other technologies, such as robotics and artificial intelligence, to create more efficient and effective manufacturing systems.

Conclusion

In conclusion, 3D printing is having a significant impact on the electronics industry, enabling the rapid production of complex electronic components and devices. The benefits of 3D printing in electronics include rapid prototyping, increased complexity, reduced production costs, and improved product performance. While there are challenges and limitations to be addressed, the future of 3D printing in electronics is bright, with many companies and research institutions investing heavily in this technology.